Designed to minimise the

effects of rail traffic noise

ABOUT

THE PROJECT

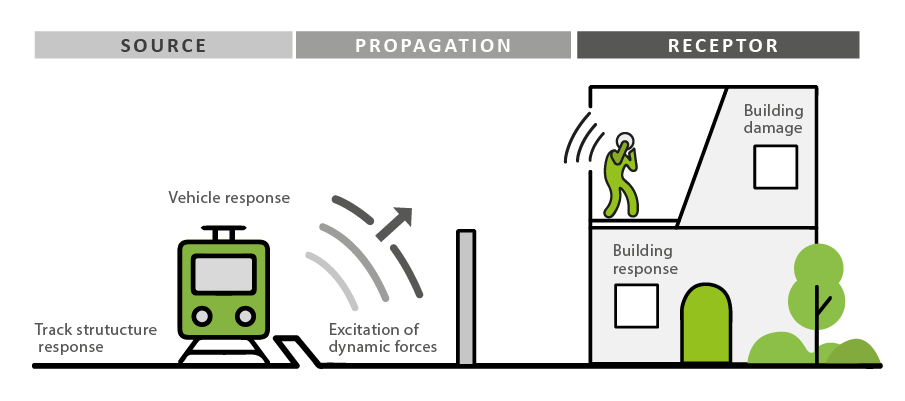

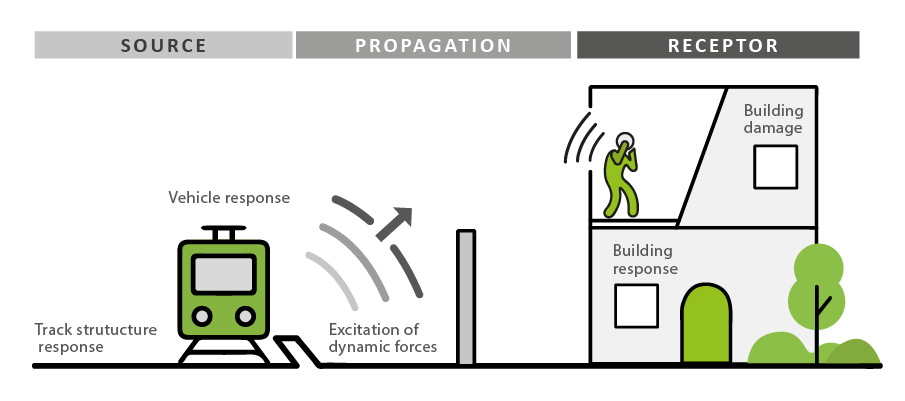

Railway transport is the mode of transport which is the most sustainable, has the lowest energy consumption, takes up the least space and leaves the smallest carbon footprint in comparison with any other mode of land or sea transport. In spite of this, the noise generated by this mode of transport poses a great environmental challenge.

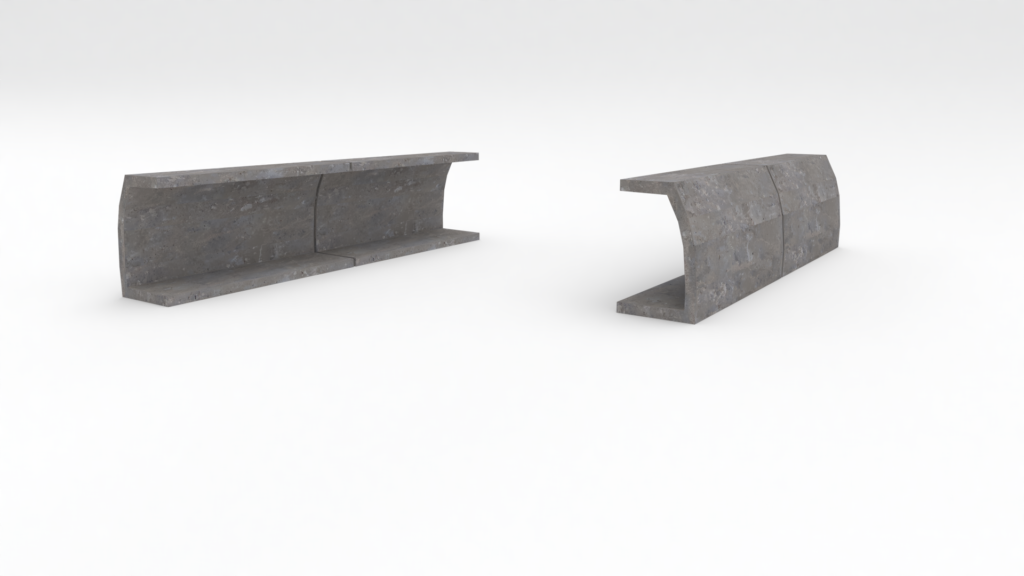

Therefore, and considering that the currently applied noise barriers are not ideal solutions to railway noise, the project “Inbrail – Innovative noise barriers for railways” aims to develop an innovative noise barrier solution, specifically designed to minimise the effects of rail traffic noise.

GOALS

The main goal for this project is that this type of solution become highly competitive in comparison with existing solutions on the market, at the technological, economic, sustainability and visual impact levels.

Act as effective

noise barriers

Reduce their

environmental

and visual impact

Low-height

solutions with

optimized geometry

Modular nature from precast concrete

ACTIVITIES

A1 – Activity 1 | Technical Specifications and Requirements

This activity aims to define the technical requirements and specifications to which the solution to be developed will have to be bound. This is a very comprehensive activity, since it will have to define not only the technical specifications that the product (acoustic barrier) will have to meet, but also to define the requirements and implications of its implementation in the context of the railway system.

A2 – Activity 2 | Development

The activity aims at the preliminary design of the optimized acoustic barrier solution through the numerical modeling of its acoustic and structural behavior, also incorporating a task dedicated to the compatibility of the solution given the different requirements. The numerical study of the different configurations will allow defining the optimal geometry of the solution, taking into account not only the acoustic and structural requirements, but also the foundation conditions and the aesthetic and environmental framework of the proposed solution. Note that this activity assumes a joint action of the teams of the various co-promoting entities (FEUP, UC and MEEC), as well as a very significant interaction with Activity 4, from which relevant material parameters will be obtained for the theoretical modeling.

A3 – Activity 3 | Production and Installation

This activity will be carried out in sync with activities 2 and 4. On the one hand, it will receive inputs from these two activities and, on the other hand, it will determine outputs for these activities. The objective of this activity is to develop the production and installation process for the realization of the final product. For this, several solutions will be studied throughout the project period, according to.

The barrier geometries studied;

The foundation solutions studied;

The materials whose application will, in the meantime, be considered;

The structural solutions that, in the meantime, are foreseen;

The installation restrictions for the application of this type of barrier that are perceived in the meantime.

A4 – Activity 4 |Evaluation and Experimental Analysis

This activity aims at the preliminary experimental characterization, i.e., in the laboratory, of the acoustic and structural performance of the components of the product to be developed. This activity presents a strong interconnection with activities A2 and A3, since it provides information for defining the numerical studies to be developed in activity A2, as well as experimentally validating particular aspects of the models developed in the activities previously described.

A5 – Activity 5 | Prototypes

The present activity aims to evaluate and demonstrate the efficiency of the proposed product in real operating conditions, thus showing the feasibility and suitability of the proposed solution. Thus, prototypes will be produced with the configurations measured through the studies carried out in the activities described above, which will be installed in the selected experimental fields (Carregado experimental field and Metro do Porto experimental field). The prototypes developed will then be explored in order to assess their efficiency in mitigating the noise perceived at the reception points due to rail traffic with different types and speeds of circulation.

A6 – Activity 6 | Technical Management and Quality

This activity aims at the technical, administrative, and financial coordination in the different phases of the project in order to guarantee the fulfillment of the objectives in an effective and efficient way, ensuring quality control in all processes.

A7 – Activity 7 | Dissemination

The goal of this activity is to disseminate the results of the project, seeking to leverage the advantages obtained by its development, particularly in terms of its applicability in the railway domain. In this way it aims essentially at:

Project promotion;

Dissemination of scientific and technical results, which are not covered by Industrial Property protection mechanisms;

Valorization and exploitation of all results with potential economic and social value;

Promotion of the generation of value and knowledge.

CONSORTIUM

The development of this project will be supported by a consortium established among three highly qualified entities: Mota-Engil Engineering and Construction (with its vast accumulated experience in the prefabrication industry), Coimbra University (scientific knowledge and experience in sound performance of different mitigation solutions), and finally Porto University Faculty of Engineering (global performance of railway systems). The project is also supported by two railway manager administrations (as partners), namely Metro do Porto and Infraestruturas de Portugal. The project entails a total investment of the order of 1 million euros.

Contac Us

Geral:

inbrail@mota-engil.pt

© 2022 INBRAIL – Innovative noise barriers for railways